The Role of Guardrails in the Workplace As Fall Prevention and Protection

Safety Guardrails are effective not only in preventing falls, but other types of accidents you may not have even considered. By providing a physical barrier between the worker and a potential hazard, guardrails prevent injury before protection is required. They are commonly used in construction sites (especially on scaffolds), industrial facilities (any height location), and other similar environments to help protect workers from falls, by preventing falls from elevated locations. When guardrails are installed safely and properly, as well as maintained, guardrails can be a reliable form of precaution for fall protection and can significantly reduce some risks of serious injuries in workplaces. However, it is important to note that the effectiveness of guardrails can depend on various factors. These factors include, but are not limited to: their design, material, installation method, maintenance, as well as any unforeseen condition that may arise as a result of a specific industry's job requirements. Also worthy of note, you can maximize their effectiveness by following any and all industry standards, guidelines, conduct regular inspections, and always make any necessary repairs/upgrades as promptly as possible.

What Are the Different Types of Guardrails?

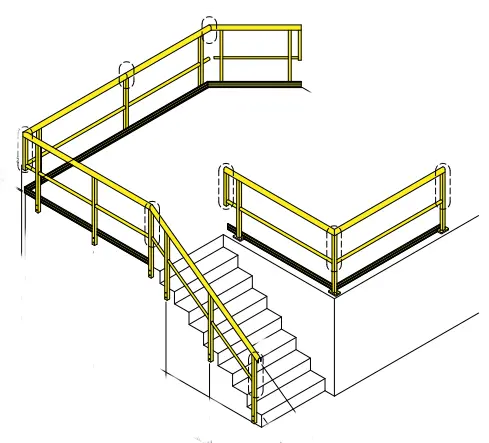

Knowing your rails! Safety Guardrails that is! - There are several types of guardrails that are available to be used to protect workers from falls, slips leading to falls, and more other hazards in the workplace, that you may have thought, including:

- Top Rail Guardrails: - These are the most common type of guardrails. Top rail guardrails consist of a horizontal rail that is mounted at the required height.

- Mid Rail Guardrails: - These rails are installed halfway between the top rail and the walking surface. Mid Guardrails are design to provide an additional level of protection.

- Toe Board Guardrails: - These low-level guard railings are installed along the edge of a platform or walkway. The serve to prevent workers from tripping or possibly falling over the edge of the surface.

- Netting Guardrails: - Much like they sound these are made of mesh material that is stretched across a frame. These Mesh netting safety guardrails and used to prevent falling objects from crashing to the guard from heights.

- Cable Guardrails - Made of vertical cables that are then tensioned between posts, and used to provide a barrier.

- Free Standing Guardrails - A freestanding systems is one that can be easily moved, or repositioned, to allow it to be a more accessibly transient barrier. This makes them ideal for temporary, or semi-permanent fall protection applications of many kinds.

- Portable Guardrails - My favorite, these lightweight, collapsible systems can be most easily transported and set up in a variety of locations of any guardrail safety system.

- Scaffold Guardrails - This safety measure are guardrails that are designed specifically to be used on a scaffolding system. Consisting of a horizontal top rail and a mid rail, Scaffold Guardrails are best designed to protect workers from falling from their scaffold platform. Possibly the one of the scariest falls for a construction worker in my personal opinion!

The exact type of guardrail used will depend on your work environment, job, and the specific working conditions. The height of the fall hazard, the weight of workers and equipment, as well as the movement of same matter greatly when selection the best guardrail type to best prevent falls in your specific environment. Remember that it is important to select the most appropriate type of guardrail for each specific application. Do your best when selecting the right guardrail goes a long way to ensure that workers are protected from as many fall hazards as possible.

Guardrails - Common Questions & Answers

-

What is the OSHA required height for guardrails?

Answer: OSHA requires that guardrails be 42 inches high for general industry and 46 inches high for construction sites. -

Are guardrails required on ALL elevated surfaces?

Answer: Under regulations, Guardrails are required on ANY elevated surfaces, which are four feet or higher, above a lower surface level. - Why Should guardrails use toe boards?

-

What is the maximum gap allowed between the guardrail and the walking surface?

Answer: 4 Inches - The maximum gap allowed between the guardrail and the walking surface is 4 inches. -

How do you determine the strength of a guardrail system?

Answer: The strength of a guardrail system is determined by a load of 200 pounds applied in any direction, and it's capability of sustaining the weight. -

Should I be aware of any special requirements for guardrails on scaffolding systems?

Answer: Yes - Scaffold Guardrails must be able to withstand a load of at least 125 pounds applied in any direction. -

How often should guardrails be inspected?

Answer: Guardrails must be inspected as regularly as possible. Regular inspection helps ensure they are in good working condition. You can then be assured a properly inspection guardrail can provide adequate fall protection. -

Can guardrails be modified or repaired in the field?

Answer: Yes. Guardrails can be modified or repaired in the field. All guardrails must still meet the required safety standards. -

Are there any specific or special materials that must be used for guardrails?

Answer: No. There are no specific materials required for guardrails. They must meet the required safety standards. -

How can you determine the appropriate type of guardrail for your specific application / workplace?

Answer: The elevation height of the work surface, as well as risk potential for falls. -

What happens if any guardrail system does not meet safety requirements?

Answer: If a guardrail system does not meet safety requirements: first it must be repaired or replaced immediately,ensure workers safety first. Compliance failure with safety regulations can result in possible fines and other penalties.

Misconceptions About Guardrail Safety

- Guardrails are not required for low-risk areas.

- Guardrails only protect against falls from height.

- Guardrails only need to be installed on the perimeter of a building.

- Guardrails are a one-size-fits-all solution.

- Guardrails do not need to be inspected or maintained regularly.

- Guardrails are not required for low-risk areas.

- Guardrails only protect against falls from height.

- Guardrails only need to be installed on the perimeter of a building.

- Guardrails are a one-size-fits-all solution.

- Guardrails do not need to be inspected or maintained regularly.

- Guardrails are not necessary in areas where workers wear personal protective equipment.

- Guardrails can be installed without professional help.

- Guardrails are only for outdoor use.

- Guardrails can be made from any material.

- Guardrails do not need to meet safety standards.

- Guardrails are only for commercial buildings.

- Guardrails are only for high-risk work areas.

- Guardrails can be adjusted or modified without professional help.

- Guardrails are too expensive for small businesses.

- Guardrails are not required for areas with low traffic.

Guardrail Manufacturers: Where to Purchase Guardrails

- 3M Fall Protection: A global conglomerate with a focus on fall protection solutions.

- Capital Safety: A leading producer of personal protective equipment and fall protection systems.

- DBI-Sala: Known for their high-quality and reliable fall arrest equipment.

- Guardian Fall Protection: Offers a range of fall protection products, including guardrails and safety harnesses.

- Honeywell Miller: A leading provider of industrial safety products, including fall protection equipment.

- Kee Safety: Offers a wide range of fall protection products and services, including guardrails.

- PAS Systems: A leading manufacturer of fall protection equipment, including guardrails and safety harnesses.

- Protecta: Known for their innovative fall protection solutions and high-quality products.

- Skylotec: A leading producer of fall protection equipment and systems, including guardrails.

- Tractel: A well-respected provider of fall protection equipment, including guardrails and safety harnesses.

Guardrail OSHA Regulations: Quick Reference

OSHA generally requires guardrails to abide by the following:- Provide a 42-inch minimum height along open-sided floor or platform areas

- Withstand a minimum 200-pound force in any direction

- Be capable of preventing workers from falling off the side

- Be securely attached to the surface or structure

- Have midrails, screens, mesh, intermediate vertical members, solid panels, or equivalent

- intermediate structural members to provide protection from falling

- Have toeboards, when necessary, to prevent tools, debris, or materials from falling over the edge.

- 29 CFR 1926.501(b)(1) - General requirements for fall protection

- 29 CFR 1926.451(g)(1) - Scaffolds: general requirements

- 29 CFR 1910.23(e)(3) - Guarding floor and wall openings and holes

- 29 CFR 1910.29(b) - Fall protection systems and falling object protection criteria

- 29 CFR 1926.503(a) - Training requirements for fall protection

- 29 CFR 1926.502(k)(1) - Personal fall protection systems criteria and practices

- 29 CFR 1910.29(i) - Design and construction requirements for ladder safety systems

- 29 CFR 1910.28(b)(9) - Portable ladders: clearance

- 29 CFR 1910.28(b)(8) - Portable ladders: stability

- 29 CFR 1910.29(b)(13) - Guarding of holes in walking-working surfaces.